SY Series Hank Dyeing Machine

|

Main Features:

● It is suitable for dyeing, bleaching, refining cotton, wool, artifical wool, acrylic. It can use for both pretreatment and after treatment.

● The space between the hank spindles can be adjusted according to different length hanks.

● Adopting precision direction changing device, it can change the dye liquor direction automatically to keep level hanks.

● Compact designed circulating pump can adjust the running sped by multilevel gears according to different dyeing techniques.

● The two machines can be combined together in serious to avoid color difference.

|

|

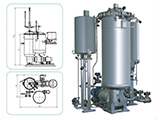

Typical Sturcture:

● The machine body which bring into contact with dye liquor is made of high quality anti-corrosion stainless steel.

● Equipped with high efficiency stainless steel axial flow pump.

● Two sets of hank spindles.

● The dyeing liquor is even circulated.

● Stainless steel feeding pump(Y20 above).

● Mixing , feeding , refluxing , rinsing device of adding material barrel ( above 200).

● Safety sample taking device.

|

|

Optional

● Automatic, semi-automatic control.

● Full automatic control of the paint barrel.

● The main pump is controlled by frequency converter.

● Adding material barrel and feeding pump (below Y-20)

● Dosing system.

● Handcart and hank cabinet.

|

|

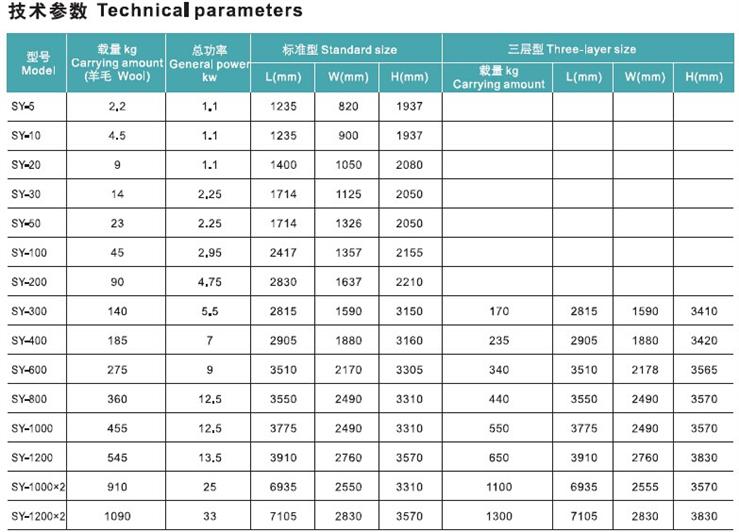

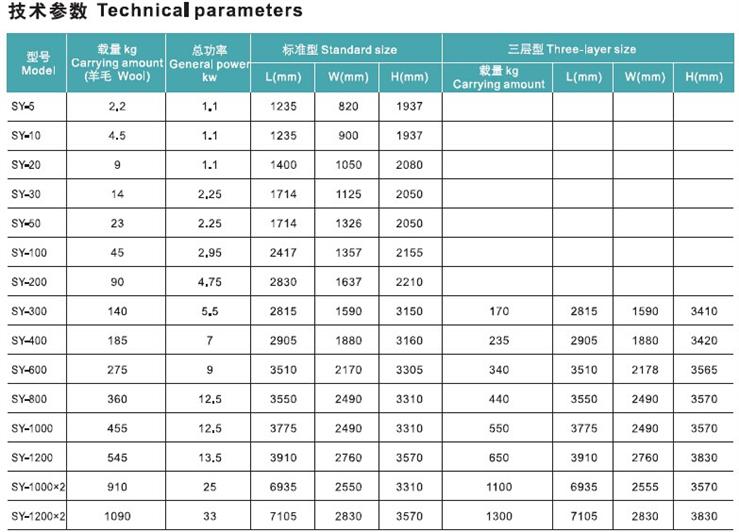

Tech Data

Max working temperature : 98℃.

Temperature rising rate: 20℃ to 98℃ 30minutes

(according to the steamy pressure 6kg /cm2).

Temperature cooling rate: 98℃ to 80℃ 15 minutes

(according to the cooling water pressure 3kg/cm2).

|