Yarn Dyeing And Finishing Machinery

Location: Home > Yarn Dyeing And Finishing Machinery

SSH80 Hank Yarn Dyeing Machine

|

Application Scope

The machine is used for high-temperature,high-pressure disperse dyeing of filament polyester,mercerized and embroidery thread,artificial silk,synthetic fiber,as well as skein dyeing.

MAIN STRUCTURE AND COMPOSITION

- All the parts contacting dye liquor are made of stainless steel.Vat body and cover are cover are locked with lockong ring and air pressure seal device.It is easy,flexible and reliable to open cover.

- The machine employs advanced high-performance homemade high-head dyeing pump without air turbidity.Under high temperature and high pressure sufficient water can be supplied for uniformly dyeing without stains and piling.

- With use of worm gearing the machine has the features of small volume ,light weight ,self-locking,etc.

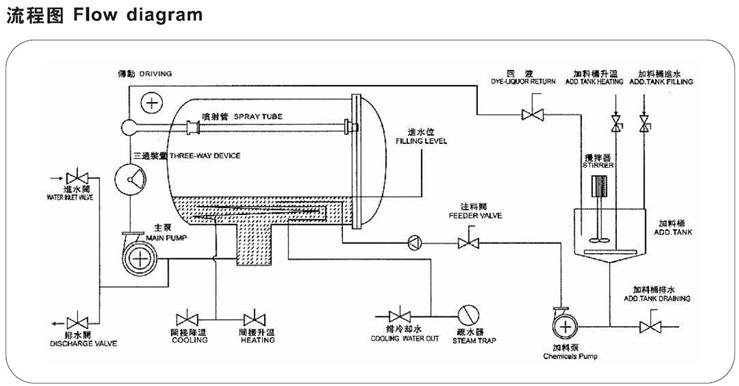

- Dye liquor circulating form:Dye liquor in vessel enters water division boxes and jet tubes through circulating pump to perform timing spray dyeing of skein and return,thus repeating circulation.

- Heating form:Use steam to provide direct and indirect heating.

- Electrical unit is controlled automatically with interval,positive and negative regulation.It is convenient to operate.

MAIN PROCESSING PARAMETERS

- Number of jet tubes:2-6 pcs

- Efficient length of jet tube:1500mm

- Capacity of yarn,yarn tape hung on each jet tube:15kg

Capacity of shoelaces on each tube:About 2500m - Bath ratio:1:8-1:15

- Working temperature:≤140°C

- Working pressure:≤3kg

- Speed of circulating pump:1400r/min

- Head of circulating pump:≥12m

- Flow of circulating pump: 120m³/h

- Motor of circulating pump:Counting according to 2kw per tube

IMPORTANT POINTS ABOUT SAFETY

- Enclosed electrical control box can't be opened during operation.

- Never make adjustment and oil filling during operation.

- Never make living maintenance.

INSTALLATION

- The machine as an integrate type needs a 12cm thick even cement foudation.Particularly when installing the machine should be keep leveling.

- Water pump is firmly located with expansion screws.

|

Model |

Number of tubes |

Nominal Capacity(Kg) |

General Power(Kw) |

Dimensions(L×W×H)mm |

|

SSH80-2-650 |

2 |

8 |

4 |

2000×2400×1700 |

|

SSH80-2-1500 |

2 |

20 |

5.8 |

2000×3500×1700 |

|

SSH80-3-1500 |

3 |

30 |

6.8 |

2200×3500×1700 |

|

SSH80-4-1500 |

4 |

40 |

7.15 |

2340×3800×1870 |

|

SSH80-6-1500 |

6 |

60 |

11.35 |

2600×3800×2050 |

|

Related Products: |